Power Tong

- We provide Power Tong for Drill Pipe, Tubing, Casing & Sucker Rod.

- Higher degree of mechanization and larger torque.

- With hydraulic lifting equipment.

- Performs safety, labor-saving and high-efficiency.

- Torque Control system and Hydraulic Power Unit could also be equipped.

- Drill Pipe Power Tong

- Casing Power Tong

- Tubing Power Tong

- Sucker Rod Power Tong

- Contact Us

Please check above buttons for more type ↑↑↑

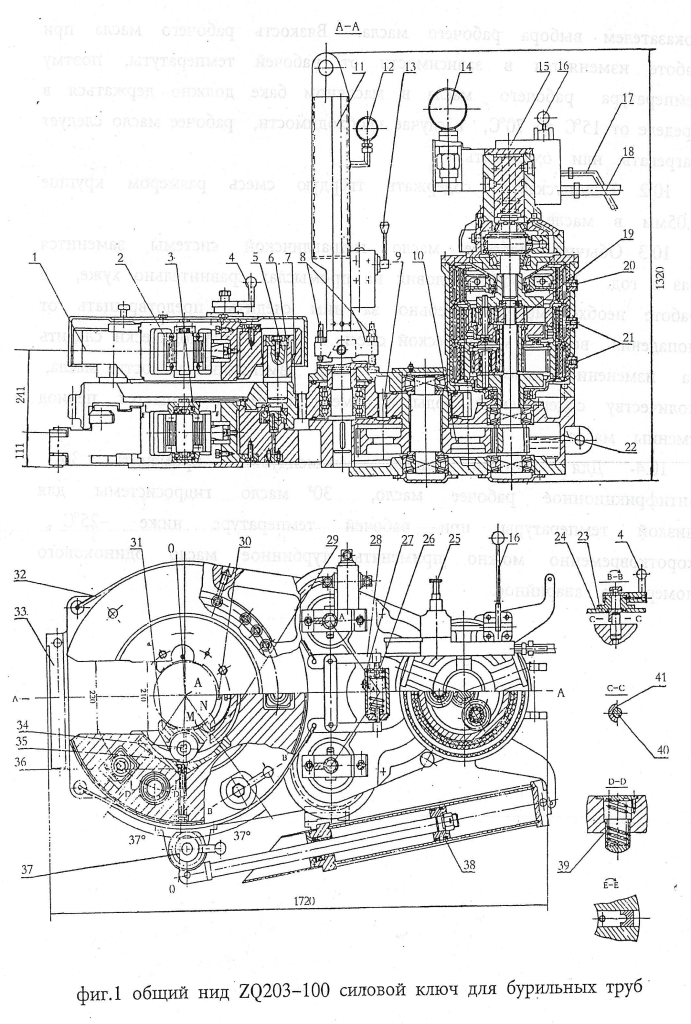

Drill Pipe Power Tong

ZQ series of drill pipe power tong marked with III is developed types from ZQ203-100 power tong. The power tong can be fixed on the accommodation track for the front and back walk. It can pass across the wellhead and go to the mouse hole for working. Master tong can move upward and downward. Walk and lift of the tong can be remote controlled and automatically handled. Especially suitable for the occasion with small wellbay surface.

| Model | ZQ203-125 | ZQ203-100 | ZQ203-100A | ZQ203-100B | ZQ162-50 | ZQ127-25 | |

| Size range | mm | 127-203 | 121-203 | 121-203 | 121-203 | 85-162 | 65-127 |

| in | 3 1/2coupling | 3 1/2coupling | 3 1/2coupling | 3 1/2coupling | 2 3/8coupling | 2 3/8coupling | |

| 8body | 8body | 8body | 8body | 5body | 3 1/2coupling | ||

| Max.torque | kN.M | 125 | 100 | 100 | 100 | 50 | 25 |

| ft.lbf | 92200 | 73750 | 73750 | 73750 | 36880 | 18440 | |

| Speed of tong Hi. | rpm | 40 | 40 | 40 | 40 | 60 | 65 |

| Speed of tong To. | rpm | 2.7 | 2.7 | 2.7 | 2.7 | 4.1 | 10.5 |

|

Hydraulic system pressure rating |

Mpa | 20 | 16.6 | 16.6 | 16.6 | 16 | 12 |

| Psi | 2900 | 2400 | 2400 | 2400 | 2320 | 1740 | |

|

Hydraulic system pressure rating |

L/min | 114 | 114 | 114 | 114 | 120 | 180 |

| gpm | 30 | 30 | 30 | 30 | 32 | 48 | |

|

Stoke of shifting cylinder |

mm | 1500 | 1500 | 1500 | / | 1000 | 1000 |

| in | 59 | 59 | 59 | / | 39.4 | 39.4 | |

|

Moving distance of tong |

mm | / | / | / | 0-3000 | / | / |

| in | 0-59 | ||||||

|

Lifting distance of tong |

mm | / | / | 0-485 | 0-1800 | / | / |

| in | 0-19 | 0-31.5 | |||||

| Overall dimensions | mm | 1720×1050×1750 | 1700×1000×

1400 |

1700×1000×

1400 |

1750×1650

×2050 |

1570×800

×1190 |

1110×790

×820 |

| in | 68×41×69 | 67×39×55 | 67×39×55 | 69×65×81 | 62×31×47 | 44×31×32 | |

| Weight | Kg | 2600 | 2400 | 2500 | 3250 | 1500 | 620 |

| Ib | 5730 | 5290 | 5510 | 7165 | 3310 | 1360 | |

Part list

| Item | Name | Item | Name |

| 1 | floating body | 21 | pneumatic type for low speed |

| 2 | die | 22 | low case body |

| 3 | inserts for jaws rack | 23 | sleeve |

| 4 | locating handle for the upper tongs | 24 | brake disc |

| 5 | pin | 25 | Relief valve |

| 6 | sleeve | 26 | left-hand and right-hand screw |

| 7 | rotary | 27 | adjusting tube |

| 8 | adjusting bolts | 28 | connecting rod |

| 9 | idler | 29 | jaw frame |

| 10 | gear | 30 | plug screw |

| 11 | suspension rod | 31 | jaw |

| 12 | air pressure gauge’ | 32 | brake band |

| 13 | bi-directional air valve | 33 | door |

| 14 | shockproof pressure gauge | 34 | jaw pin |

| 15 | Oil motor | 35 | jaw roller |

| 16 | hand-reversing valve | 36 | cam |

| 17 | inlet pipe | 37 | locating handle for low tongs |

| 18 | outlet pipe | 38 | air cylinder for gripping |

| 19 | sun-gear | 39 | spring |

| 20 | pneumatic type for high speed | 40 | locating pin |

| 41 | locating turning pin |

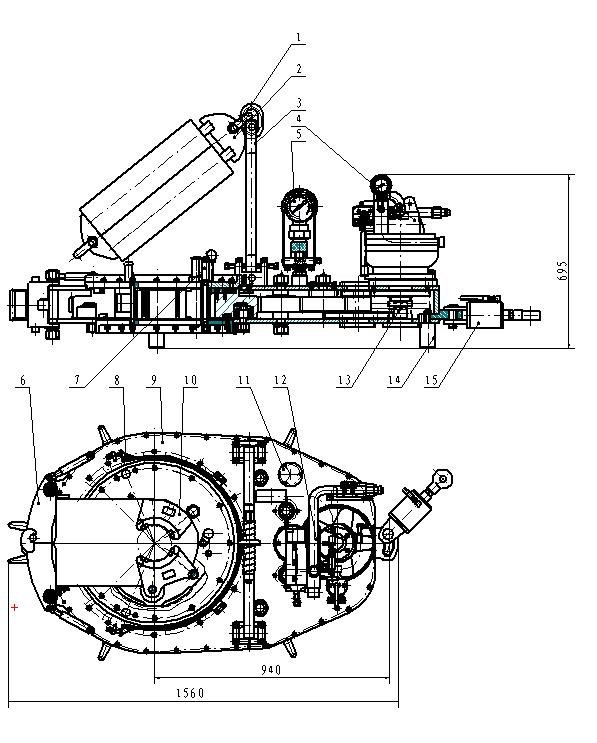

Casing Power Tong

TQ series of casing tongs are widely used for making-up or breaking-out of casings or pipes. The casing tong features high-efficiency, safety, reliability, labour-saving, and can ensure connection quality. Tong head is designed as open and is fitted with two jaws which can ensure reliable gripping. Air type clutch is utilized as gear shifting mechanism, so it is possible to change gear under running. The series of casing tongs can be configured with torque device to perform computer monitoring and managing on pressure, torque and rounds. The casing tong has been granted with National Invention Patent. The casing tongs are designed and manufactured according to SY/T5074 and 7K “Specification for Drilling Equipment”

| Model | TQ178/16 | TQ340/35 | TQ356/55 | TQ178/16Y | TQ340/35Y | TQ356/55Y | TQ508/70Y | TQ610/60Y | TQ340/85Y |

| Size range (inch) | 4″-7″ | 4 1/2″-13 3/8″ | 4 1/2″-14″ | 4″-7″ | 4 1/2”-13 3/8″ | 41/2″-14″ | 9 5/8″-20″ | 9 5/8″-24″ | 4 1/2″-13 3/8″ |

| Max working pressure (Mpa) | 18 | 18 | 16.6 | 18 | 20 | 20 | 20 | 18 | 18 |

| working flow Rate (l/min) | 110-160 | 110-160 | 110-140 | 110-160 | 110-170 | 110-170 | 110-170 | 120-180 | 110-170 |

| Air pressure (Mpa) | 0.5-0.9 | 0.5-0.9 | 0.5-0.9 | / | / | / | / | / | / |

| Max torque (Kn.m) | 16 | 35 | 55 | 16 | 35 | 55 | 70 | 60 | 85 |

| Jaw speed (RPM) | 9-79 | 3.5-86 | 4-70 | 9-79 | 8-90 | 4.8-61 | 4-43.6 | 5-45 | 3.2-45 |

| Item | Part name and description |

| 1 | Break out |

| 2 | Spring hanger assembly |

| 3 | Hanging bracket |

| 4 | Hydraulic motor |

| 5 | Hydraulic torque measuring device |

| 6 | Safety door |

| 7 | Reverse pin |

| 8 | Brake band |

| 9 | Transmission gear case |

| 10 | Jaw assembly |

| 11 | Speed-measuring gear |

| 12 | Hydraulic system |

| 13 | Shifting mechanism |

| 14 | Support foot |

| 15 | Torque cylinder |

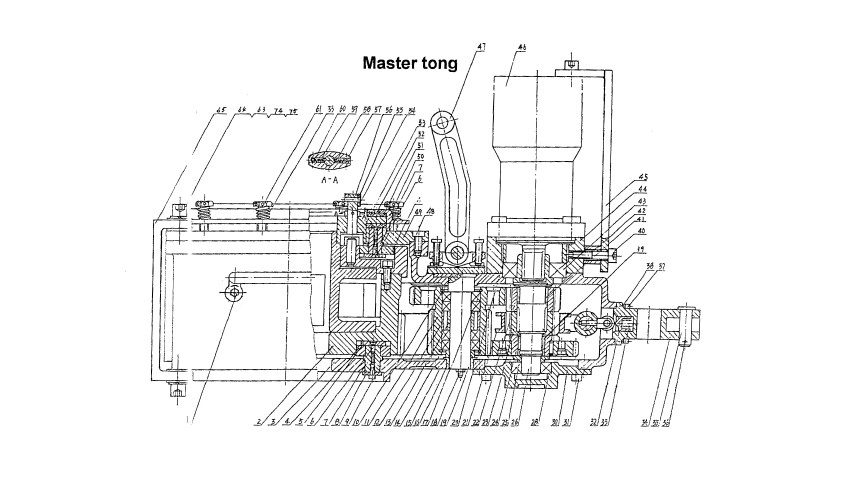

Tubing Power Tong

XYQ Series of Oil Pipe Power Tong is used for quick make-up/break-out in well service operation. The tong is equipped with hydraulic backup tongs and use inner curve cam to clamp. The products are designed and manufactured strictly according to API 7K Spec Standard.

| Model | XQ89/3C | XQ114/6YB | XQ140/12YA | XQ140/20Y |

| Pipe size range of master tong | φ60-89 | φ60-114 | φ73-140 | φ60-140 |

| 23/8”-31/2” | 23/8”-41/2” | 27/8”-51/2” | 23/8”-51/2” | |

| Pipe size range of backup tong | φ60-114 | φ60-114.5 | φ73-156 | φ60-156 |

| 23/8”-41/2” | 27/8”-41/2” | 27/8”-31/2” | 23/8”-61/8” | |

| High gear rated torque | 1270N.m | 1650N.m | 2600N.m | 2300N.m |

| 937ft-lbs | 1217ft-lbs | 1918ft-lbs | 1696ft-lbs | |

| Low gear rated torque | 3300N.m | 6070N.m | 12000N.m | 20000N.m |

| 2434ft-lbs | 4477ft-lbs | 8851ft-lbs | 14751ft-lbs |

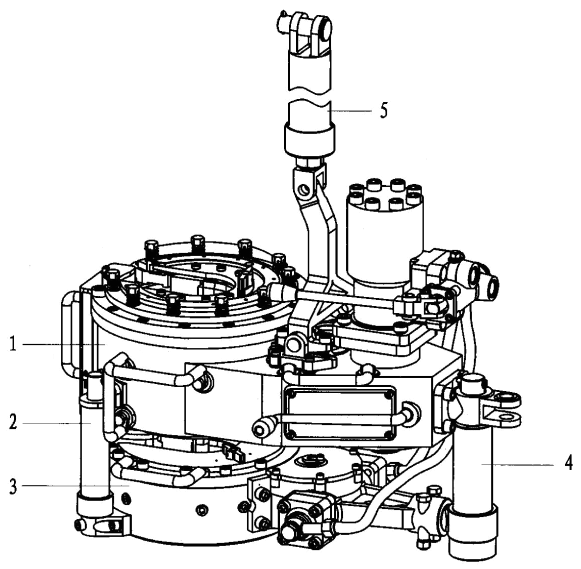

Sucker Rod Power Tong

Model XQ28/2.6 hydraulic power tong is an improved type of XYQ1.8 which is used to make up and break out sucker rod thread in Well Service. This product has the following features:

A. The structure is compact, concise and light. Master tong is driven by a low-speed large torque hydraulic motor that matches with a manual control valve. The backup tong is just like a spanner. The total weight is approximately equal to XYQ1.8.

B. The operating is briefness and convenience with high efficiency. Put the respondence size jaw set into master tong and the respondence size glutting into backup tong, turning the reset knob incorrect direction then can make up and break out sucker rod by operating manual control valve. Two speed, snapping at low speed, spinning at high speed.

C. Large low gear torque, especially suitable for the instance that is difficult to break out sucker rod thread.

| Model | XQ28/1.8 | XQ28/2.6 |

| The range of master tong | Sucker rod GYG 16 19 22 25 28 Φ48~60 oil tube 5/8″~11/8″ |

Sucker rod GYG 16 19 22 25 28 5/8″~11/8″ |

| the range of Back tong | Sucker rod GYG 16 19 22 25 28 Φ48~60 oil tube 5/8″~11/8″ |

Sucker rod GYG 16 19 22 25 28 5/8″~11/8″ |

| High gear rated torque | 700 N.m 516 ft-lbs |

1000 N.m 737.5 ft-lbs |

| Low gear rated torque | 1800 N.m 1327.6 ft-lbs |

2600 N.m 1918 ft-lbs |

| High gear rated speed | 104 r/min | 98 r/min |

| Low gear rated speed | 40 r/min | 32 r/min |

| Rated the system pressure | 10 Mpa 1450 psi |

10 Mpa 1450 psi |

| Maximum supply oil | 65 L/min 17 gpm |

80 L/min 21 gpm |

| Overal dimension L×W×H(mm) |

543×334×404 21.4″×13.1″×15.9″ |

670×383×490 26.4″×15.1″×19.3″ |

| Removed quality (including back clamp) |

105 kg 231 lbs |

100kg 220lbs |

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.