BOP Testing Unit

- Running stability, small size, light weight, low noise, easy maintenance and high efficiency.

- Can be controlled locally and remotely, and monitor, record, print and track the recording value.

- Can be used both in factory and in the field installed on a vehicle.

- In accordance with API 16D.

- Three type of pump: Electric, Pneumatic and Electro-Pneumatic.

- Technical Specification

- Description

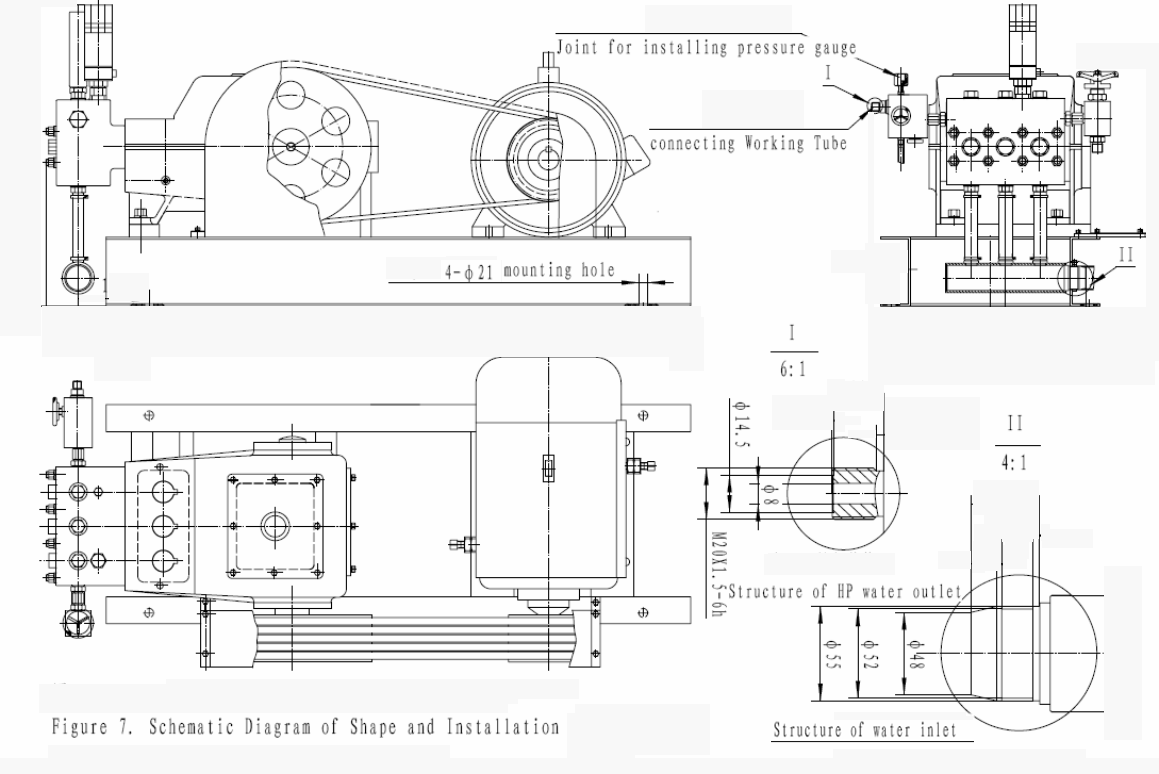

- Drawing

- Contact Us

Pneumatic high pressure test unit

| Model | Pneumatic pump | Rated input pressure

(Mpa) |

Working pressure

(Mpa) |

Volume of oil tank(L) | Rated explosion pressure

(Mpa) |

Automatic recorder

(set) |

||||

| 1:30 | 1:100 | 1:60 | 1:200 | 1:225 | ||||||

| QT21 | 1 | 0.7 | 21 | 45 | ||||||

| QT21-J | 1 | 0.7 | 21 | 45 | 1 | |||||

| QT35 | 1or1 | 0.58 | 35 | 100 | ||||||

| QT35-J | 1or1 | 0.58 | 35 | 100 | 1 | |||||

| QT70 | 1 | 1 | 0.7 | 70 | 100 | 84 | ||||

| QT70-J | 1 | 1 | 0.7 | 70 | 100 | 84 | 1 | |||

| QT140 | 1 | 1 | 0.7 | 140 | 100 | 168 | ||||

| QT140-J | 1 | 1 | 0.7 | 140 | 100 | 168 | 1 | |||

| QT140A | 2 | 2 | 0.7 | 140 | 100 | 168 | ||||

| QT140A-J | 2 | 2 | 0.7 | 140 | 100 | 168 | 1 | |||

| QT140B | 1 | 1 | 0.7 | 140 | 168 | |||||

| QT140B-J | 1 | 1 | 0.7 | 140 | 168 | 1 | ||||

| QT140C | 1 | 1 | 0.7 | 140 | 100 | 168 | ||||

| QT140C-J | 1 | 1 | 0.7 | 140 | 100 | 168 | 1 | |||

| QT200 | 1 | 1 | 0.9 | 200 | 100 | 225 | ||||

| QT200-J | 1 | 1 | 0.9 | 200 | 100 | 225 | 1 | |||

| QT200A | 2 | 2 | 0.9 | 200 | 100 | 225 | ||||

| QT200A-J | 2 | 2 | 0.9 | 200 | 100 | 225 | 1 | |||

Electric pressure test unit

| Item | Specifications | |

| Model | DT35-J | DT105-J |

| Working pressure | 35Mpa | 105Mpa |

| Supply power voltage | 380VAC, 3 Phase 4 Wire | 380VAC, 3 Phase 4 Wire |

| Motor power | 30 Kw | 55 Kw |

| Displacement of electric pump | 2300L/H | 1560L/H |

| Ambient temperature | -10 to +50℃ | -10 to +50℃ |

| Outlet | NPT1 Male | NPT1/2 Female |

| High pressure hose | Working pressure:70 Mpa

ID:12.7mm Outlet:NPT1 Female |

Working pressure:105 Mpa

ID:12.7mm Outlet:M24×1.51 Female |

Electro-Pneumatic high pressure test unit

| Item | Specifications | |

| Model | DQT70-J | DQT105-J |

| Working pressure | 70Mpa | 105Mpa |

| Supply power voltage | 380VAC, 3 Phase 4 Wire | 380VAC, 3 Phase 4 Wire |

| Air source pressure | 0.7Mpa(100psi) | 0.7Mpa(100psi) |

| Air consumption | 1.5m³/min | 1.5m³/min |

| Ambient temperature | -10 to +50℃ | -10 to +50℃ |

| Triplex pump displacement | Displacement:50L/min | Displacement:21L/min |

| Pneumatic pump displacement | 1:30 Pneumatic pump 180ml/stroke

1:100 Pneumatic pump 30ml/stroke |

1:60 Pneumatic pump 90ml/stroke

1:200 Pneumatic pump 14ml/stroke |

| Bursting pressure | 86Mpa | 168Mpa |

BOP Testing Unit, also called pressure test pump which is recommended for high pressure testing of BOP stacks, choke and kill lines, Christmas trees and any other type of equipment requiring high pressure static testing. Test Units are available in unit-mounted, portable, skid-mounted and high flow electric driven styles. Accessories include stand-mounted chart recorders and high pressure hose assemblies. High Pressure Test Units are provided in working pressure ranges from 5,000 to 20,000 PSI.

Accessories of pressure test unit, including stand-mounted chart recorders and high pressure BOP Accumulator Units, meet the design specification specified in API 16D. Customized pressure test pump is available to assure reliable control of the BOP stack with adequate reserve for continuous operation under emergency conditions.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of API, ISO, GOST, etc.