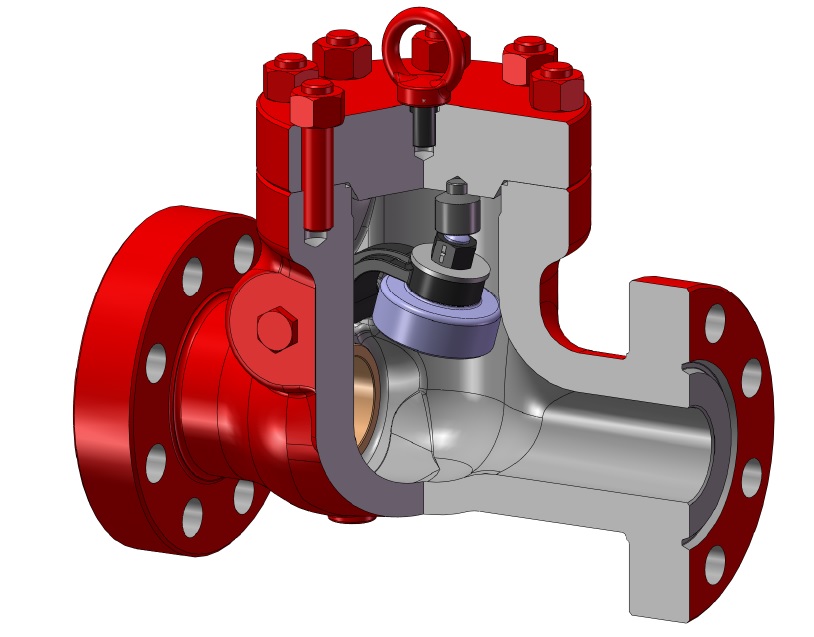

Check Valve

- Sealing is energized by flow fluid pressure, sealing performance gets better while pressure increasing.

- Hard-faced sealing surface and sulfur-resistant core material assure fine performance of wear-resistant and corrosion-resistant.

- Integral forged body with fine mechanical properties.

- Check valve shall be hydro tested prior to delivery for safe performance.

- Technical Specification

- More Details

- Structure

- Contact Us

Product Name: 6A Swing Check Valve, Lift Check Valve, One-Way Valve, Non-Return Valve

Nominal Bore: 1-13/16″ – 7-1/16″

Material: AISI 4130 (Integral Forged)

End Connection: 6A Flange

Standards Applied: 6A, 16C, NACE MR0175

Pressure Rating: 2000 PSI to 15000 PSI

Material Class: AA, BB, CC DD, EE, FF

Temp Class: L, P, R, S, T, U, V

Performance Requirement: PR1, PR2

Product Specification Level: PSL1, PSL2, PSL3, PSL4

Paint Color: Red or Customized

Application: Mud Choke Manifold, Kill Manifold, Wellhead Christmas Tree Connection

6A Check Valve, also referred to non-return valve, or one-way valve, is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction. An important concept in check valves is the cracking pressure which is the minimum upstream pressure at which the valve will operate. We can produce both swing type check valve and lift type check valve. Available in bore sizes from 1-13/16″ to 7-1/16″ and pressure ratings from 2,000 to 15,000 PSI. The standard material is forged AISI4130 alloy. All of our Check Valves are fully designed, manufactured, and tested as per 6A and 16C standards and have been widely used on oilfield wellhead Christmas tree and manifolds with reliable performance.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.