Coupling

- 100 % customer satisfaction for Quality and Reliability.

- Superior Plating, Painting and Packaging Processes.

- After machining all couplings undergo 100% thread inspection.

- Colour Coding and Marking as per Standard.

- MTRs available for all coupling.

- Casing Coupling

- Tubing Coupling

- Sucker Rod Coupling

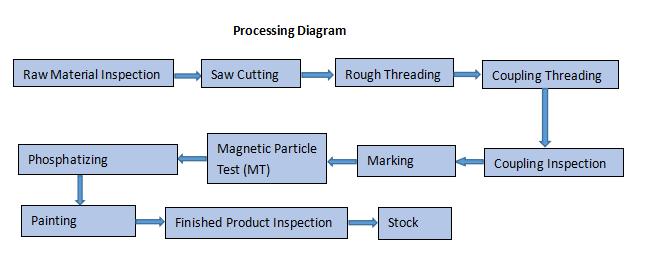

- Processing Diagram

- Contact Us

Please check above buttons for more type ↑↑↑

Casing Coupling

Hot sale sizes: 7″ casing coupling, 9-5/8″ casing coupling, 13-3/8″ casing coupling, 20″ casing coupling

Hot sale threads for casing coupling: BTC, LTC, STC

More information:

| Casing Coupling | |

| Pipe O.D. | 4-1/2″, 5″, 5-1/2″, 6-5/8″, 7″, 7-5/8″, 8-5/8″, 9-5/8″, 10-3/4″, 11-3/4″, 13-3/8″, 16″, 18-5/8″, 20″ |

| Grade | H-40, J-55, K-55, C-75, L-80, N-80, C-95, P-110, L80-13CR |

| Thread Connection | BTC, STC, LTC |

| Option | Electro-zinc plated |

| Phosphorization | |

Tubing Couplings

Hot sale sizes: 2-3/8″ tubing coupling, 2-7/8″ tubing coupling, 3-1/2″ tubing coupling, 4-1/2″ tubing coupling

Hot sale threads for tubing coupling: EUE, NUE, API 5CT

More information:

|

Tubing Coupling |

|

|

Pipe O.D. |

1.900″, 2-3/8″, 2-7/8″, 3-1/2″, 4″, 4-1/2″ |

| Grade |

J-55, C-75, L-80, N-80, C-95, P-110 |

|

Thread Connection |

EUE, NUE |

| Option |

Electro-zinc plated Phosphorization |

|

Standard |

API 5CT, API 5B |

Sucker Rod Coupling

Advanced thermal spraying technology is adopted to melt Ni alloy and other high wear-resisting materials on the blank surface of the collar after high temperature flame spraying, so as to reduce the friction coefficient between the anti-wear collar and the oil pipe to 0.01, which is an effective combination of high hardness and low friction, thus improving the service life of the rod and pipe in oil exploitation.

| Type | Grade | O.D(mm) | Minimum length(mm) | Hardness | Weight (kg) |

Standard reference |

| 3/4″ | 19-T | 41.05~41.43 | 101.6~103.17 | 56-62HRA | 0.65 | API 11B |

| 7/8″ | 22-T | 45.75~46.13 | 45.75~46.13 | 56-62HRA | 0.8 | API 11B |

| 1″ | 25-T | 55.35~55.73 | 55.35~55.73 | 12-23HRA | 1.15 | API 11B |

| Coupling pipe grade identification by paint color | |

| Grade | Color Coding (Painted Outside) |

| H-40 | Black |

| J-55 or K-55 | Green |

| N-80 | Red |

| M-65 or L-80 | Red with one Brown Band |

| L-80 Type 9CR | Red with two Yellow Bands |

| L-80 Type 13CR | Red with one Yellow Band |

| C-90 Type 1 | Purple |

| C-90 Type 2 | Purple with one Yellow Band |

| T-95 Type 1 | Silver |

| T-95 Type 2 | Silver with one Yellow Band |

| C-95 | Brown |

| P-110 | White |

| Q-125 Type 1 | Orange |

| Q-125 Type 2 | Orange with one Yellow Band |

| Q-125 Type 3 | Orange with one Green Band |

| Q-125 Type 4 | Orange with one Brown Band |

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.