Frac Hose

- Meets API Spec Q1, API Spec 7K, API Spec 16C, API Spec 16D.

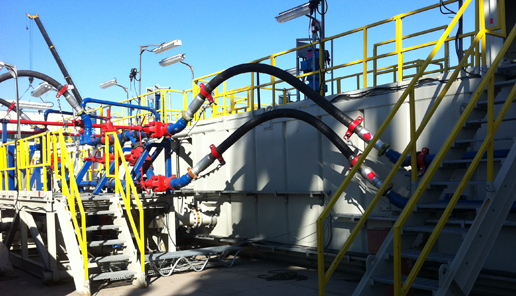

- Frac hose appllying for acidizing fracturing, sand fracturing and hydraulic fracturing during well completion operations.

- It can deliver water-based, oil-based, foam, acid-based etc.fracturing fluids under high pressure.

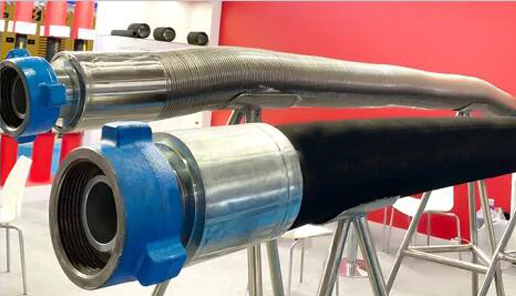

- Frac hose are usually composed of three parts: Inner layer,Enhanced layer and Outer rubber layer.

- Frac hose connection include integral hammer union, integral flange or other types.

- Technical Specification

- Description

- Contact Us

| Specification Size | Inside Diameter | Outer Diameter | Working Pressure | Test Pressure | Weight |

| inch | mm | mm | psi | psi | kg/m |

| 2″ | 45 | 95 | 15000 | 22500 | 18 |

| 51 | 103 | 15000 | 22500 | 20 | |

| 2-1/2″ | 58 | 121 | 15000 | 22500 | 26 |

| 64 | 128 | 15000 | 22500 | 30 | |

| 3″ | 70 | 135 | 15000 | 22500 | 34 |

| 76 | 141 | 15000 | 22500 | 38 | |

| 4″ | 89 | 165 | 15000 | 22500 | 50 |

| 102 | 171 | 15000 | 22500 | 56 | |

| 5″ | 120 | 210 | 15000 | 22500 | 68 |

| 127 | 215 | 15000 | 22500 | 90 | |

| 6″ | 130 | 220 | 15000 | 22500 | 112 |

| 140 | 240 | 15000 | 22500 | 130 | |

| 2″ | 44 | 106 | 20000 | 30000 | 24 |

| 51 | 112 | 20000 | 30000 | 26 | |

| 2-1/2″ | 57 | 126 | 20000 | 30000 | 32 |

| 64 | 133 | 20000 | 30000 | 36 | |

| 3″ | 69 | 142 | 20000 | 30000 | 44 |

| 76 | 145 | 20000 | 30000 | 46 |

Frac hose meets API Spec Q1, API Spec 7K, API Spec 16C and API Spec 16D. It is used as pipeling, appllying for acidizing fracturing, sand fracturing and hydraulic fracturing during well completion operations. It can deliver water-based, oil-based, foam, acid-based etc.fracturing fluids under high pressure.

Product Structure: Inner layer: Polymer composite; Inner diameter type: full flow; Enhanced layer: High strength and flexible steel wire wrapped in multiple layers; Outer rubber layer: wear-resistant and weather resistant synthetic rubber.

Product advantages:Adopts Polymer composites as wear-resistant layer, with rubber protection behind the wear-resistant layer. Adopts Polymer composite materials as identification warning.Yellow and red inner rubber layers will be seen After the wear-resistant layer of polymer composite is completely worn.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of API, ISO, GOST, etc.