Screen Pipe

- Resistant to corrosion.

- Sufficient column and collapse strength.

- Well prevention of sand and grit.

- Suitable for different geological environment with different type screens.

- Improve well productivity and efficiency.

- Slotting or perforation size can be customized.

- Technical Specification

- More Details

- Drawing

- Contact Us

| Basic information | Product Name | Well Screen pipe |

| Size Range | 1.9 ~ 20 in | |

| Certification | API 5CT | |

| Material | Alloy steel | |

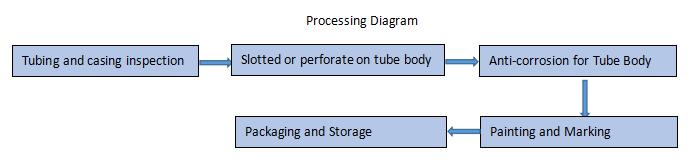

| Processing Type | Laser cutting | |

| Thread Type | NUE, EUE, STC, BTC, LTC | |

| Characteristic | high quality anticorrosion | |

| Perforated screen pipe | Application | API tubing & casing 1.9 in to 20 in |

| Steel grade | J55, K55, L80, N80, P110 | |

| Holes Diameter | As requested | |

| Holes Density | As requested | |

| Length of pipe | As requested | |

| Slotted screen pipe | Application | API tubing & casing 1.9 in to 20 in |

| Steel grade | J55, K55, L80, N80, P110 | |

| Slot Width | ≥0.10±0.03mm | |

| Slot rate | As requested | |

| Slot shape | straight pattern, staggered pattern, spiral pattern | |

| Length of pipe | As requested |

Well Screen Pipe is a filtering device used in oil / gas / water wells.

The main function of screen pipe is to prevent sand and grit. Different geological environment causes screen pipes with different grade and type, including Slotted Screen Pipe, Perforated Screen Pipe, Premium Mesh Sand Screens, Pre-packed Well Screen, Wire Wrapped Screen, Bridge Slotted Screen, Metal Mesh Sand Screen, etc.

Screen selection can have a far-reaching effect not only on the life of your downhole equipment and tubular, but also on long-term well productivity and efficiency. From conventional to specialty sand screens can help you to increase tool longevity and achieve optimal production.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of API, ISO, GOST, etc.